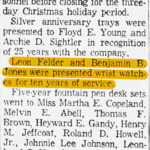

Leon Felder

Manufacturer

Manufacturer

Machinist, Foundry Worker at Gibbes Machinery Co 1951-1991

Leon Felder

Manufacturer

Manufacturer

Machinist, Foundry Worker at Gibbes Machinery Co 1951-1991

Born in 1921 in Summerton, South Carolina, Leon Felder grew up in the rural Lowcountry as part of a sharecropping family. Sharecropping was a system created after the Civil War in which tenant farmers worked the land in exchange for a share of the crop yield. By the 1920s, the system had trapped many families, including the Felders, in cycles of debt and poverty. Racial segregation and limited access to education and economic opportunities defined life for Black families in this region.

Leon Felder was drafted into the U.S. military in February 1942 when the United States entered World War II. Like many African American soldiers, he served in a segregated military. The war exposed many African Americans to broader perspectives and created a growing expectation for civil rights and equality upon their return home.

After the war, Leon returned home to his wife and began building a family. In rural areas like Summerton, the sharecropping system persisted, offering little chance for upward mobility. Seeking better opportunities for his growing family, Leon and his family relocated to Columbia, South Carolina, in late 1950. Columbia was evolving from a textile-centered economy to a more diversified industrial hub during this era. The growth of manufacturing and infrastructure projects provided new job opportunities.

Leon secured a position as a helper at Gibbes Machinery Co., a prominent industrial equipment and automobile supplier in Columbia. For 40 years, he became a fixture in the company, rising through the ranks and working in several capacities, including machinist, foundry worker, and metal press operator.

As a machinist, Leon would have used precision lathes, milling machines, and grinders to fabricate and repair auto parts. His work required an understanding of blueprints, measurements, and tolerances to ensure that each part met specifications. Machinists like Leon were essential in keeping production lines running and ensuring the quality of finished products.

In the foundry, Leon was responsible for molding and casting metal components. This demanding work involved pouring molten metal into sand molds, removing castings, and performing finishing operations such as grinding and polishing. Foundry work was hot, physically taxing, and required close attention to safety and quality.

Leon also operated giant presses in the metalworking shop. These presses applied immense force to shape metal sheets. Operating such equipment required strength, precision, and an understanding of mechanical systems to troubleshoot any issues during production.

Even as Gibbes’s production slowed in the 1980s, Leon continued to work part-time, a testament to his value as a skilled and dedicated employee. His expertise and commitment were indispensable until the company ultimately closed its doors in 1991, marking the end of an era for Columbia’s manufacturing sector.

Leon Felder’s life journey exemplifies resilience and determination in the face of systemic challenges. From his humble beginnings in Summerton to his decades-long career at Gibbes Machinery Co., Leon contributed to his community and his family’s prosperity through hard work and a commitment to learning. His mastery and dedication to his craft remain a testament to the essential role of skilled workers in American industry.

Leon was in his free time an excellent checkers player, storyteller, and handyman. He was always making things with his hands. He was an outdoorsman, a family man, and a Deacon.

Education

6th Grade Formal Education

Sponsor(s)

Anthony Scott, grandson